Top things to look out for when selecting the right composite decking for you

Are you looking at doing a decking project but overwhelmed with the range of composites on the market?

You’re not alone!

With the abundance of composite decking options now available, it can be difficult selecting the right board for your project. In this article we will identify some key things to look out for when determining the best composite decking board for you.

- Performance history

- Quality

- Testing and compliance

- Be wary of unsubstantiated claims

- Service and support

- Warranty

Performance history:

The real test of a composite decking board is how well the boards have performed over time. Unfortunately, the New Zealand composite timber decking market has seen too many failures, so choosing the right board is paramount.

Not all brands perform the same and investing in your outdoor living space is a big deal – you don’t want to have to redo your outdoor living space because the deck has failed.

When you talk to your composite decking supplier be sure to ask them questions like:

- How long have their composite decking boards been around for?

- How are the boards holding up?

- What are the most common issues/complaints received?

The greatest indicator of future performance is the past.

When Ekodeck started in 2009 the biggest questions we were asked back then was “how will it go over time? and “will it fade?” Despite the heap of tests we got done, the scientists and engineers told us “Nothing beats real world testing”.

Now, after 12 years of being around, with installations taking place all over Australia and New Zealand every week, we don’t get these questions anymore. Deck owners and builders alike have seen for themselves how Ekodeck’s composite decking boards have held up over time.

Quality:

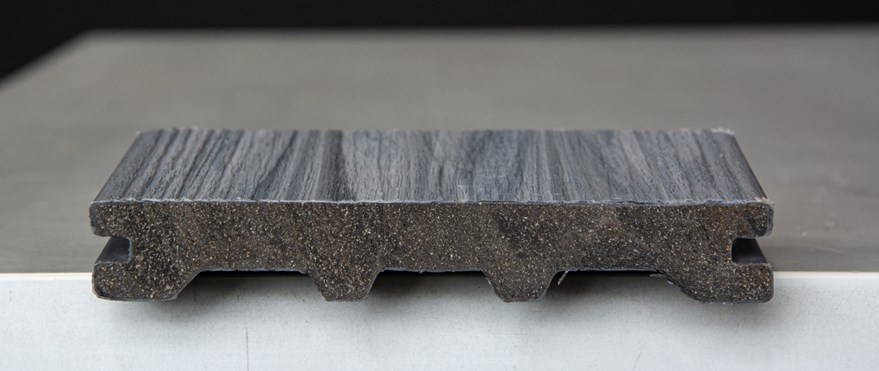

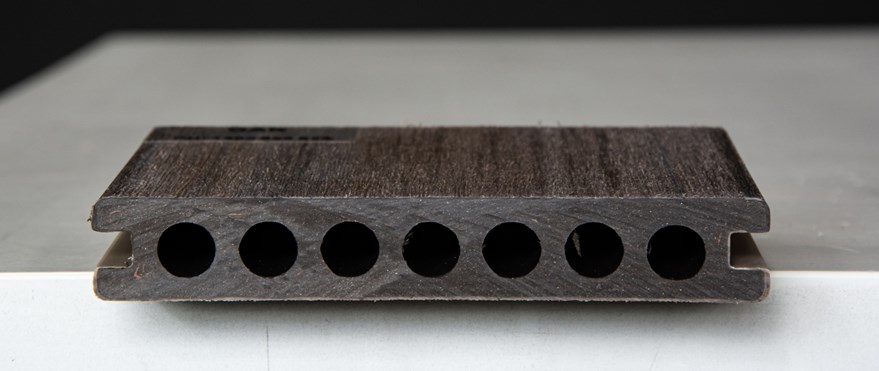

Typically, all composite decking boards are extruded through a mould, then go through various stages of finishing to obtain a desired look, texture, finish and feel. However, not all composite decking boards are made to the same standard.

Over time various components, tools, moulds or stages of this process wear out. Also, when working with recycled materials close attention needs to be paid to consistency to ensure a reliable product is produced at the end of the day.

Ekodeck has its own specialist team ensuring all boards are made within a strict set of guidelines – from dimensional variances to colour and finish. The machines and tools are regularly inspected, replaced or fixed to ensure you’re getting a quality product from one batch to another.

One of the biggest secrets is our particle size – smaller timber fibres means they are better encapsulated by the plastics and bonding agents, which provides better protection and fade resistance. Some brands have larger particles and its no wonder why they have a reputation for fading over time.

It’s a good idea to compare samples from various suppliers to inspect the difference in quality and finish.

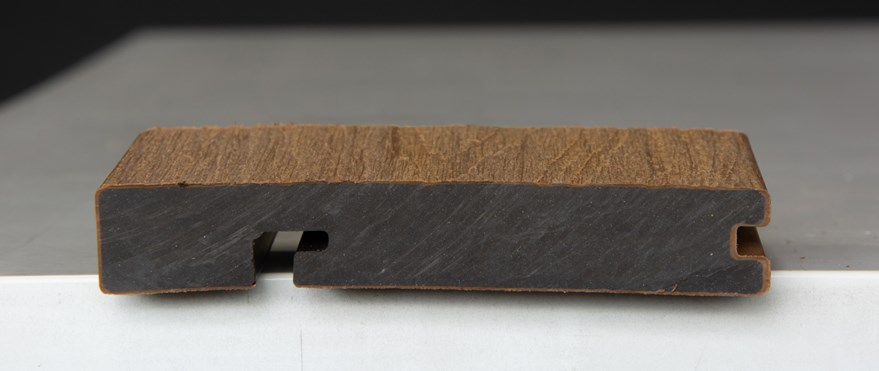

Another differentiating factor of Ekodeck boards is the thickness of the wrap. When comparing Ekodeck co-extruded boards, such as our Designer Series, note the thickness of the wrap compared to others on the market.

Testing and compliance:

There are standards, both domestic and international, when it comes to composite timber decking. Whether it be load limitations, durability testing, slip resistance or burning behaviour, it’s important that your chosen composite decking supplier is transparent about the tests that have been undertaken and the results of those tests.

Load limitations are critical and as 450mm joist spacings are commonplace in New Zealand, it’s important that your chosen composite decking brand declares the load limits of the board.

That being said, many composite decking suppliers are often not aware of the standards that their boards need to comply with to be able to be sold on the New Zealand market. In fact, some don’t even allow for an installation with 450mm joist spacings.

If your decking supplier does not allow you to install to 450mm you or your builder will have to modify your existing subframe to allow for extra timber joists. This is even more costly if the deck is going on to steel.

Be wary of unsubstantiated claims:

Watch out for composite decking suppliers that make claims about their boards that they cannot substantiate.

It’s a good idea to ask your supplier to show durability results when it comes to rot and decay and termite resistance. A lot of composite decking brands make this claim, but can they verify it?

Also, slip ratings are very important, especially when it comes to ramps. Can the supplier show you their test results and do they also disclose the product’s burning behaviour and fire related characteristics? If they can’t, you know how committed they are to the New Zealand market.

When it comes to Ekodeck Decking, we have all our results, reports and certifications available for download on our website.

You can find all the technical specifications for Ekodeck Classic here and Designer Series here. You’ll find slip ratings and bushfire test reports are readily available prior to purchase, ensuring your certifier, engineer or surveyor can sign off on your project and choice of materials knowing your Ekodeck boards are compliant to New Zealand Standards.

Should you require any further information, don’t hesitate to reach out to us at [email protected] and we’ll be sure to assist you any way we can.

Service and support:

You need the comfort of knowing that your supplier is there to support you through the installation and well into the service life of the decking boards after they’ve been laid.

Ekodeck is well into it’s 12th year of supplying composite decking all over Australia and New Zealand, and by partnering with Bunnings we are held to a high standard of pre-sales and post installation service and support.

We have a national support office which looks after trade customers, DIYers, architects and specifiers alike, not to mention the 300+ Bunnings store network across Australia and New Zealand. Additionally, we have reps that cover every state and territory across the two countries who are experts in their field.

We take pride in serving all customers, because we still believe there’s nothing like old-fashioned high-quality service. If you reach out to us, we believe you’ll be able to tell the difference – if you can’t, please tell us!

If you’re still in doubt, ask yourself will your chosen composite decking supplier be around to support you now and well into the future?

Warranty:

Warranty is an interesting element to judge the best composite decking supplier by.

On the surface, you’re just comparing numbers right? The higher the number the better the warranty? Unfortunately, it’s not that simple. Can you understand the fine-print? Can the company explain it when you call them? And does the brand have a reputation to back their product when things don’t go quite to plan?

What’s the point of having a lifetime guarantee or 30+ year warranty when the company is nowhere to be found in a few years’ time?

We partner with Bunnings, the most trusted retail brand in Australia. Unlike our other composite decking suppliers, we’re unable to be disingenuous with our warranty. But given Ekodeck’s performance history – we’d back it anyway.

In summary, some of these questions go to the heart of the company and their culture. Make sure your supplier can answer you in a way that makes you comfortable with your choice. You should feel comfortable with your choice as you are able to trust the brand.

You may also like

Get started with Ekodeck

Experience our entire colour range for yourself. We deliver a sample kit complete with each colour direct to your door free of charge.